The specification of reflective road studs is generally 100mm*100mm*20mm, and the maximum height does not exceed 25mm. There are many kinds of reflectors, including reflectors, reflectors, LEDs, reflective films, etc.

Classification of Reflective Studs:

According to the material, it can be divided into:

- Cast aluminum Road Studs; 2. Plastic Road Studs; 3. Ceramic Road Studs; 4. Glass Ball Road Studs; 5. Reflective Bead Road Studs (divided into 21 beads and 43 beads, which can be combined into cast aluminum and plastic Road Studs )

According to the function, it can be divided into:

- Ordinary Road Studs; 2. Solar Road Studs; 3. Tunnel Wired Road Studs; 4. Wireless Road Studs.

According to the number of reflective surfaces, it can be divided into: single-sided Road Studs and double-sided Road Studs.

In no special circumstances, Reflective Studs refers to ordinary Road Studs.

So what are the characteristics of Solar Studs and how does it work?

Due to the continuous development of the solar energy industry, in recent years, various high-tech traffic safety facilities and products have been favored by the industry in the highway safety protection projects implemented by the country. The widespread application of these traffic safety facilities and products has played an important role in improving road safety and reducing traffic accidents. Among various traffic safety facilities or products, Solar Studs can clearly outline the contours and edges of the road in rain, fog and road bends to induce the driver’s sight, thereby eliminating road safety hazards. Solar Studs can play a very important role in delineating road contours in rainy and foggy weather and at corners, inducing the driver’s sight and eliminating potential safety hazards.

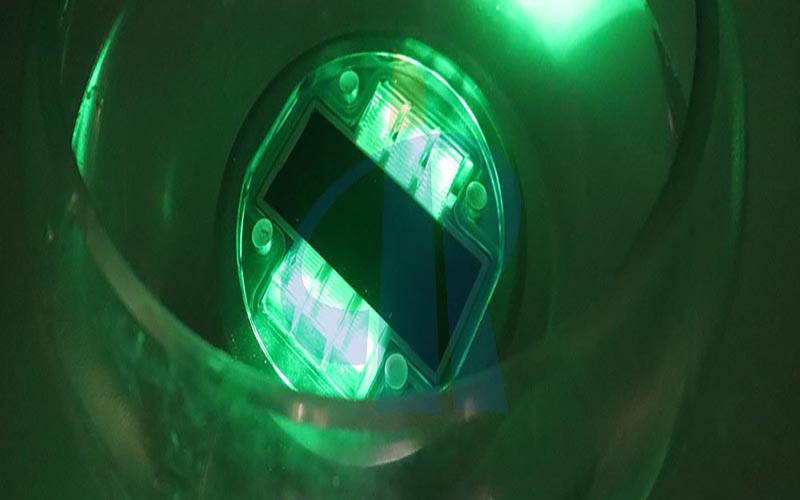

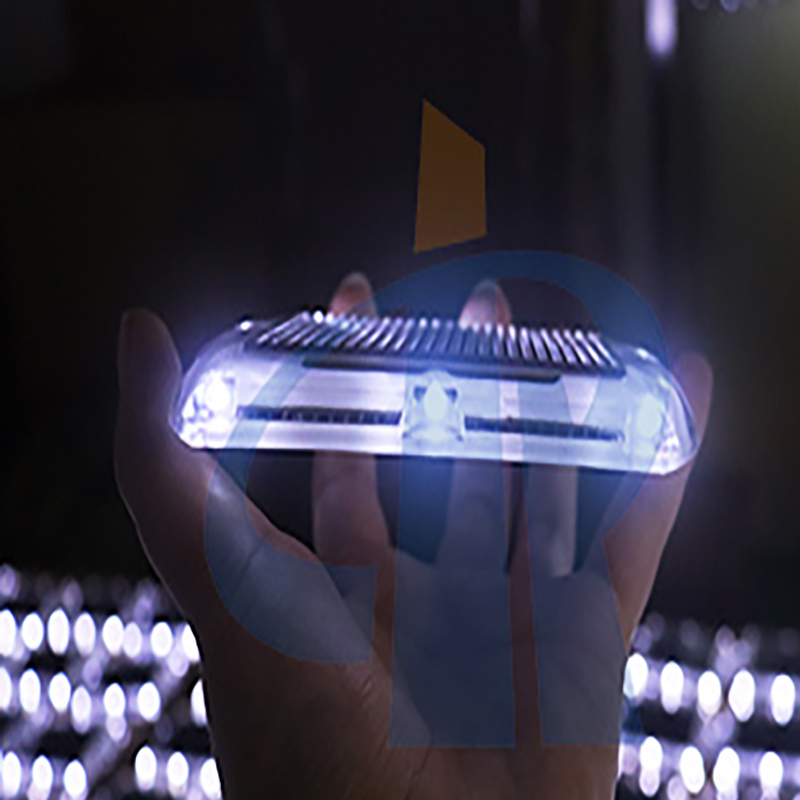

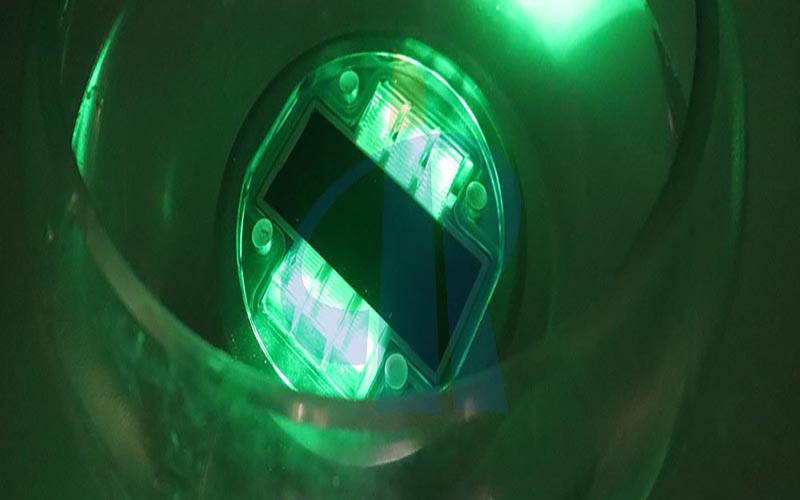

Solar Studs (Solar Road Stud or Solar Road Marker), is a kind of Road Studs, set along the road surface, used at night or in rain and fog, to indicate the direction of the road. It is made of retroreflective materials, shells, solar panels, LEDs , Control device composition, visual induction facilities with active light-emitting and passive light-reflecting performance, usually used in conjunction with markings.

Features of Road Studs

High brightness

The reflective brightness of ordinary Reflective Studs is only 300-400 MCD, while the luminous brightness of Solar Studs can reach more than 2000 MCD, which is 6-7 times that of the former. The high-intensity light can penetrate rain and fog at night, which is safe and effective for driving. Guide the direction.

Active light, dynamic warning

Solar Studs flicker at a certain frequency at night, and human vision is more sensitive to changes, so its dynamic warning effect is very strong. Active lighting can not only avoid the interference of rain and fog to the greatest extent, but also can break away from the dependence on car lights, and the visual distance is longer and the effect is better.

Solar Studs plays a very important role in delineating road contours in rainy and foggy weather and at bends, inducing the driver’s sight and eliminating safety hazards.

The working principle of Solar Studs

During the day, solar panels absorb sunlight and convert solar energy into electrical energy, which is stored in energy storage devices (batteries or capacitors). At night, the electrical energy in the energy storage devices is automatically converted into light energy (controlled by photoelectric switches) and emitted by LEDs. Bright light draws the outline of the road and induces the driver’s sight.

Solar Studs can be divided into embedded type and protruding type according to different installation positions.

The former is generally used in the midline, and the latter is generally used in the marginal line. This is because the Solar Studs installed on the centerline require particularly high pressure resistance. In order to solve this problem, the Solar Studs had to be buried in the ground, and only about 5 mm of the ground was exposed. The Solar Studs used on the edge line does not require particularly high pressure resistance, and it can still work effectively when protruding from the ground.

Solar Studs can be divided into capacitive type and battery type according to the different energy storage components. The service life of the former can reach five to seven years, and the service life of the latter generally ranges from one to three years.

Because the buried Solar Studs damage the road surface greatly, and the cost of capacitive solar road studs is too high, so the most widely used solar Studs is the raised battery.